When it comes to engines, as a car owner or prospective car owner, you must be very confident that you know such things very well. However, when many people pick up the brochures of automobile manufacturers or face some professional words in automobile advertisements, their heads will still feel short-circuited. This is actually not surprising. In today’s automobile marketing, many manufacturers like to use technical marketing to enhance the gold content of their brands or models. When we carefully explore these technologies, we will be very surprised to find that they are not so profound.

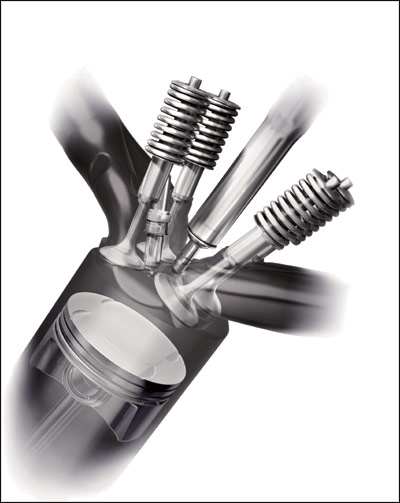

Structure diagram of Mercedes-Benz CGI direct injection technology

Looking back at the development process of the engine, the automobile engine has undergone a gradual evolution from in-line to W-type, during which various structures such as horizontal opposition and V-type have also been derived. The number of cylinders has also developed from the initial single cylinder to 16 cylinders now; Gasoline engine also experienced the transition from carburetor era to EFI era; With the development of the times, the valve structure inside the cylinder has gradually developed from the previous two-valve structure to the present multi-valve structure. Here, we can’t give you an introduction to the development of the engine one by one. Looking back at these trivial events, we can already feel that the engine has changed very obviously in just over 100 years.

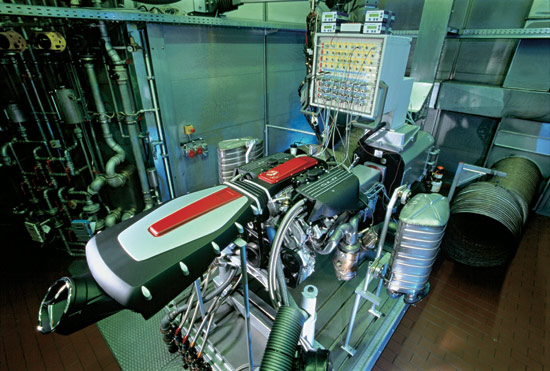

SLR’s 5.5L supercharged engine was tested on a dynamometer.

Although the progress is obvious, due to the pressure of energy and environment and in order to meet the higher and stronger power demand of consumers, the research on engines by major manufacturers is still in progress. Improving fuel economy and power is still the trend of engine technology development today. When analyzing modern engine technology, we can see that all technologies have been linked with electronic control. For example, variable valve technology has become the standard equipment of almost all engines, even in the aspect of variable valve technology, there are advantages and disadvantages, but its high popularity also confirms the positive role of this technology from one aspect. Gasoline engines are gradually introducing direct injection technology. Due to its positive impact on fuel efficiency and emissions, major manufacturers have now taken this technology as the highlight of the future development of gasoline engines. Look at the supercharging technology, although the development of this engine technology has a long history, but because it can help the engine to make a qualitative leap in power, we can still see that this technology is widely used in some high-performance vehicles today, and even abroad it has become one of the ways for some car refitters to improve vehicle performance.

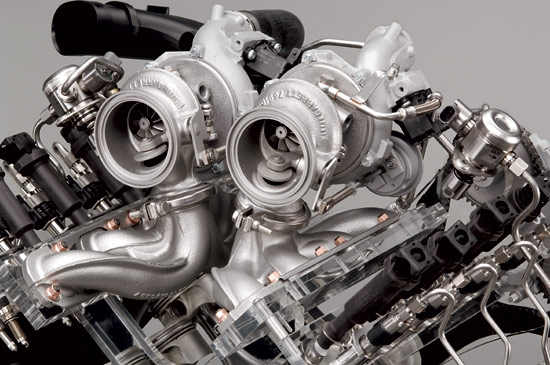

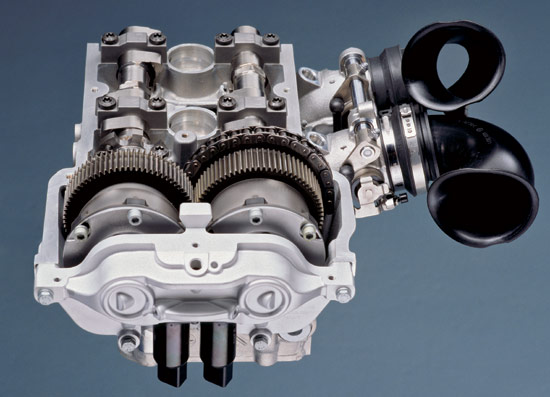

In order to reduce the longitudinal length, BMW installed the twin turbines of V8 engine in the middle of the included angle of V-shaped cylinder.

As consumers, sometimes they don’t have to pay attention to the specific development process of engines, but when purchasing vehicles, these developing technologies will inevitably become obstacles to understanding vehicles in detail. There are at least 10 names for variable valve technology of engines, such as VTEC, VVT-i, CVVT, etc. Direct injection technology also has different names similar to FSI, SIDI and HPI. These technologies, which belong to the same category, have been named by various manufacturers, which is indeed conducive to the brand promotion of manufacturers in the technical field, but consumers have not become beneficiaries. These technologies will more or less become obstacles for some consumers to buy, choose and love cars.

In order to enable current car owners, prospective car owners and more car lovers to have a more intuitive understanding of these technologies of the engine, we hereby make this topic of new engine technologies. Although variable valve technology and supercharging technology are no longer new technologies, we can see that major manufacturers are still making breakthroughs in this field. Facts have also proved that the development of the engine in these two fields has also brought us many benefits, and this benefit is constantly expanding with the development of time. I hope that the short 10-page topic can help you understand these technologies more clearly and provide some support for your car selection, car purchase and car ownership. New technology is not far away from you, just waiting for you to notice it carefully.

Variable art of valve

Consumers can always hear or see some abbreviated English words about engine technology when listening to salesmen’s explanations or reading manufacturers’ brochures themselves. After listening to this "CVVT", I will hear "VVT-i" in another store, which is really a headache for consumers who don’t know much about cars.

In fact, up to now, engine variable valve technology is no longer synonymous with advanced technology, because this technology has gradually spread in the automotive field. Because of its outstanding contribution to fuel economy and power, several major automobile manufacturers in the world have been involved in research and development in this field many years ago. However, various car manufacturers have different names in this respect, such as Honda i-VTEC, Toyota VVT-i, Hyundai CVVT, Mazda S-VT and so on. At present, there is not much difference in this technology among several major automakers, but there are still some differences in structure. Honda and Toyota, two Japanese companies, like to promote this technology most. Many consumers may feel at a loss in the face of these technical rankings. Looking at the following simple introductions of several technologies may make you more confident in the introduction of sales staff.

Structural diagram of BMW Valvetronic

BMW Valvetronic and Double-VANOS

Compared with Honda and Toyota’s high-profile publicity in this respect, BMW pays more attention to the promotion of high-end brands, so it seems to ignore its technological advantages. However, here we have to push this technology to the foreground.

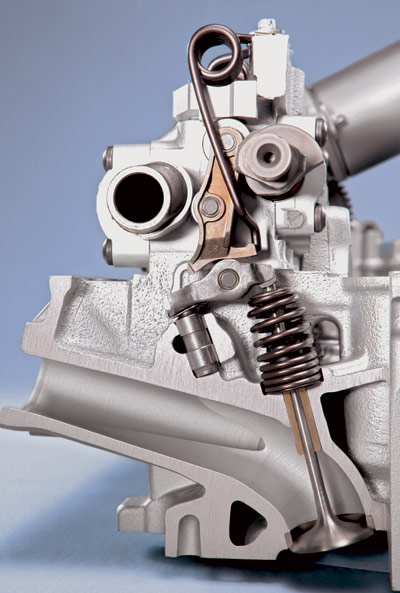

Internal structure of BMW VANOS

Valvetronic is an electronic continuous variable valve lift technology of BMW. It is worth mentioning that this technology is different from Honda’s segmented one. It transforms the axial movement of the motor into the angle change of the rocker arm through a set of worm gears, so that the valve lift can be freely and continuously variable under the control of ECU. This should be the most classic design of continuously variable valve lift so far. Although it is classic, it is often used in combination with VANOS technology. VANOS is BMW’s variable valve timing technology, and Double-VANOS is the same as Toyota’s dual VVT-i technology, which realizes continuous variable timing for the intake and exhaust of the engine. In terms of structural design, BMW’s combination of Valvetronic and Double-VANOS variable valve technology seems more convincing.

Representative model: BMW 120i

BMW 120i, which has just entered the domestic market, has been equipped with these two technologies.

This technology of BMW is very mature. At present, the inline 4-cylinder engines of BMW’s lowest-end 120i in China market have been equipped with Valvetronic and Double-VANOS technologies. This technology has obviously become the standard equipment of BMW engines, and then it may be the popularization of BMW HPI direct injection technology.

Honda i-VTEC

Honda i-VTEC has different settings on different engines.

I-VTEC is gradually upgraded from the original VTEC technology, and Honda’s application in this technology can be said to be perfect. For SOHC or DOHC inline 4-cylinder engines and SOHCV6 engines, the application methods are slightly different, but they all ensure the variable valve timing and variable valve lift technology. Honda realizes this variable process by changing the high and low speed camshafts. In order to make VTEC technology more intelligent, Honda later introduced VTC(valveoverlapcontrol) to make the variable valve timing continuously adjustable. At present, Honda’s use of i-VTEC technical terms is somewhat confusing. For example, the newly added i-VTEC technology on the new Fit L13A engine is different from that of Accord 2.4. There is no VTC technology in i-VTEC of 1.3L engine with new fit. Although SOHCV6 engine used in Accord 3.5 has VCM(VariableCylinderManagement) technology, there is no VTC technology.

Representative model: Honda Accord 2.4L

2.4L the eighth generation accord is the mainstay of the accord car series.

The i-VTEC equipped with the 2.4L in-line 4-cylinder DOHC engine used in Accord 2.4 is a more "orthodox" i-VTEC. This is because this i-VTEC system is a combination of VTEC technology and VTC technology, that is to say, its engine has continuous valve variable timing technology and segmented variable valve lift technology. With this system, ECU can automatically adjust the valve mechanism according to the driving condition of the vehicle, so as to meet the reasonable intake and exhaust requirements in each period and achieve good power performance and fuel economy.

Toyota VVT-i

Toyota VVT-i has the same influence as Honda i-VTEC.

Toyota and Honda have been secretly competing, and so have VVT-i and i-VTEC. Toyota VVT-i is developed from the original VVT, which is a continuously variable timing structure, but there is no variable valve lift technology, which is different from Honda i-VTEC. Toyota later continued to deepen this technology, and introduced the variable mechanism of exhaust end, that is, double VVT-i, on the basis of the original variable intake. In this way, the engine can use the function of intake and exhaust more effectively, and improve the power and fuel economy of the engine. In fact, Toyota does not have variable lift technology. In VVTL-i, Toyota combines VVT-i and variable valve lift technology, but the engine 2ZZ-GE equipped with this technology did not meet Euro IV emission regulations at that time, so it was not reused by Toyota.

Representative model: Toyota Corolla 1.8L

Toyota Corolla cars have introduced dual VVT-i technology.

Toyota Corolla 1.8 is equipped with 1.8L in-line 4-cylinder 2ZR-FE engine, which is equipped with Toyota dual VVT-i technology. The intake and exhaust parts have continuous variable valve timing mechanisms, which can effectively adjust the intake and exhaust of the engine during the whole operation. Although there is no variable lift technology, it is similar to Honda i-VTEC after adding valve timing to the exhaust part.